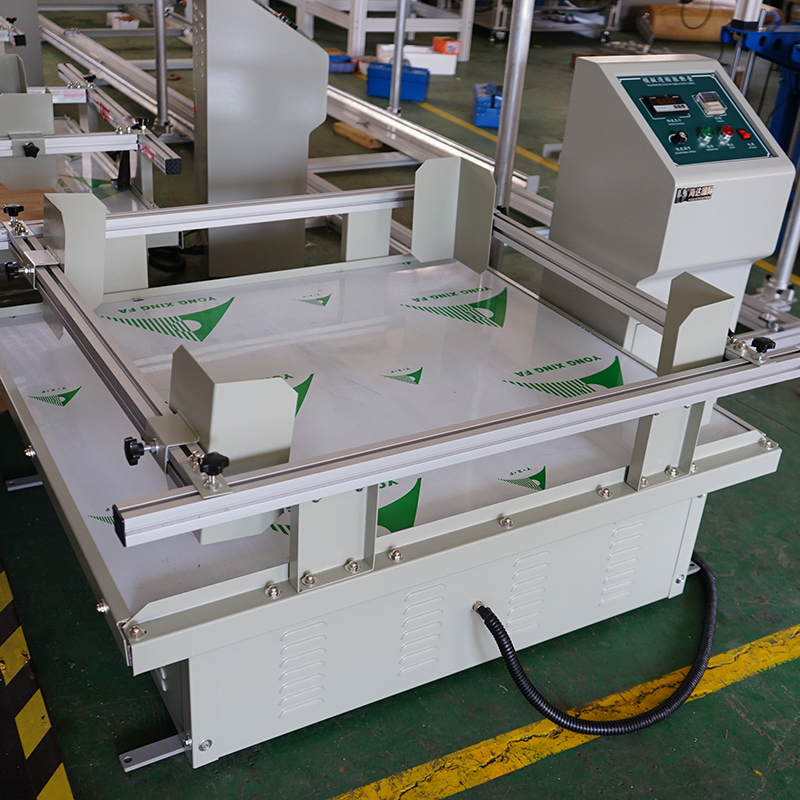

In one of the tests, I had troubles that the amplitude got higher than limits (3g) in Y-direction. We use a three step process to identify the decisions that need to be made for a productive and cost-effective vibration test, to save money, improve reliability and reduce time to market. The image below shows the Test-POD that I am testing on a single axis shaker. Blade-off vibration (engine fan blade loss and windmilling).Meeting Challenging Vibration Testing RequirementsĮlement’s vibration testing services across the US and Europe help companies meet the latest defense, aerospace, transportation and commercial requirements, including: Random vibration testing and shock testing can help ensure material stability under vibration conditions in real world environments. Our Servo-Hydraulic systems simulate high displacement low frequency events, such as Windmilling, Tire Burst, and Seismic events. We also have multi-axial simulation table (MAST) testing for squeak and rattle. For the test profiles in Question 1, a typical IEPE/TEDS 100 mV/G would be an ideal accelerometer for the low amplitude (3Gpk) sine dwell test, but would not be the best choice for the shock test as defined (50Gpk). For more information about the Element vibration testing services available in your region, contact us today.Įlement has extensive experience in vibration testing services and our vibration laboratories feature electro-dynamic and servo-hydraulic systems that can replicate low- and high-frequency conditions. Utilizing state-of-the-art control systems for vibration testing standards, we can perform field data replication as well as impart specified test levels to meet your requirements and ensure that the test specimen is up to the task. Our laboratories can perform testing procedures during electrical and hydraulic operation, as well as environmental simulation for more accurate results using a variety of vibration testing methods. With experts in critical industries across the globe, we are a single-source provider of programs with even the most complicated requirements. Vibration monitors are calibrated using the motor-driven. Used to ensure that products are robust and perform safely during operation or transit, vibration testing detects performance issues and potential failures before they start. The TK-3 Proximity System Test Kit simulates shaft vibration.

Vibration testing under laboratory conditions mimics the conditions that a product or structure might see during its lifetime.

0 kommentar(er)

0 kommentar(er)